DKBI

Description

None

* High resistance to gap extrusion.

* Particularly strong wear resistance.

* Insensitivity to shock loads and pressure peaks.

Application

None

Materials

None

TECHNICAL DATA

TECHNICAL DATA

| Temperature | -55°C/+100°C |

| Pressure | None 50 MPa |

| Speed | 1 m/s |

| Medias | None |

MATERIALS

MATERIALS

PU

Polyurethane is a material that has the elastic properties of rubber. The proportion in its composition (diisocyanate, polyol, chain extender) is determined by its properties. This material is characterised by a strong mechanical resistance, good wear resistance, high elastic modulus, good flexibility and a very good ozone and oxidation resistance.

| Chemical resistance | Pure aliphatic hydrocarbons (propane, butane) Mineral oils and greases Silicone oils and greases Water up to +50°C |

|---|---|

| Compatibility issue | Ketones, esters, ethers, alcohols and glycols Hot water, steam, alkalis, amines and acids |

| Temperature range | -30°C/+90°C -30°C / +110°C with our PUHT (short term peak at 150°C) |

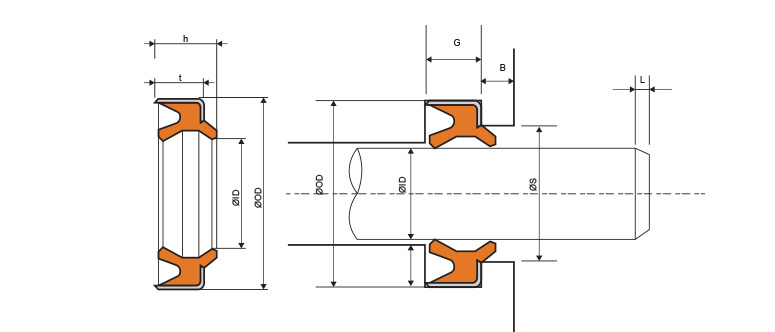

DIMENSION

DIMENSION

| Item | Rod diameter (Ød1 f8/h9) | Groove diameter (ØD1 H9) | Bore diameter (ØD2 H11) | Groove width (L1 +0/+0.20) |

|---|---|---|---|---|

| DKBI-20 | 20 | 32 | 6 | 9 |

| DKBI-25 | 25 | 37 | 6 | 9 |

| DKBI-30 | 30 | 42 | 6 | 9 |

| DKBI-32 | 32 | 44 | 7 | 10 |

| DKBI-34 | 34 | 46 | 7 | 10 |

| DKBI-35 | 35 | 47 | 7 | 10 |

| DKBI-38 | 38 | 50 | 7 | 10 |

| DKBI-40 | 40 | 52 | 7 | 10 |

| DKBI-45 | 45 | 57 | 7 | 10 |

| DKBI-50 | 50 | 62 | 7 | 10 |

| DKBI-55 | 55 | 69 | 8 | 11 |

| DKBI-60 | 60 | 74 | 8 | 11 |

| DKBI-65 | 65 | 79 | 8 | 11 |

| DKBI-70 | 70 | 84 | 8 | 11 |

| DKBI-75 | 75 | 89 | 8 | 11 |

| DKBI-80 | 80 | 94 | 8 | 12 |

| DKBI-85 | 85 | 99 | 8 | 11 |

| DKBI-90 | 90 | 104 | 8 | 11 |

| DKBI-95 | 95 | 109 | 8 | 11 |

| DKBI-100 | 100 | 114 | 8 | 11 |

| DKBI-105 | 105 | 121 | 9 | 12 |

| DKBI-110 | 110 | 126 | 9 | 12 |

| DKBI-115 | 115 | 131 | 9 | 12 |

| DKBI-120 | 120 | 136 | 9 | 12 |