HBY

Description

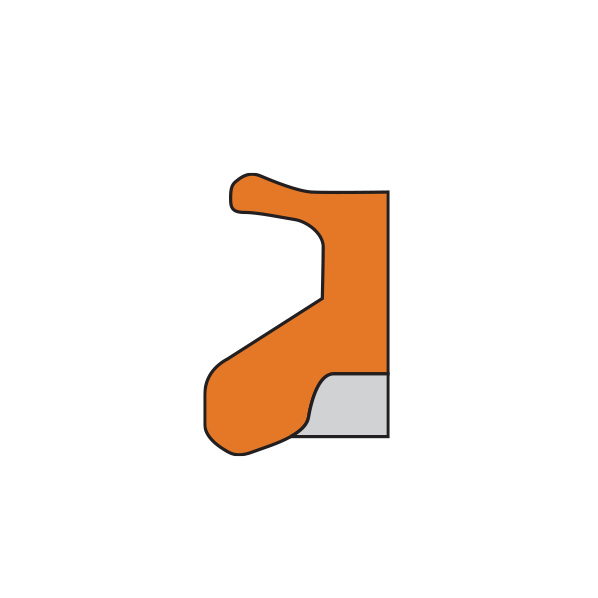

HBY is a buffer seal developed to work in conjunction with high performance rod seals. It is interchangeable with common PTFE buffer seal housings.

The seal is designed to provide a valve action to prevent excessive pressure build up in the cavity between the buffer seal and the rod seal. A polyacetal anti-extrusion ring is fitted to provide maximum extrusion resistance against shock pressure loads.

* HBY allow oils to reach the primary seal at low pressure preventing the primary seal from running dry.

* It will self energize for maximum seal ability at high pressure or during shock load to protect the primary seal from it.

* If there is ever a pressure trap, it will release the trapped pressure at the lowest level when compared to other buffers in the market.

* Easy installation.

* Long life.

Application

None

Materials

Polyurethane (PU) + Nylon (NY)

TECHNICAL DATA

TECHNICAL DATA

| Temperature | -55°C/+100°C |

| Pressure | 500kg/cm² |

| Speed | 1 m/s |

| Medias | PU+NY |

MATERIALS

MATERIALS

PU

Polyurethane is a material that has the elastic properties of rubber. The proportion in its composition (diisocyanate, polyol, chain extender) is determined by its properties. This material is characterised by a strong mechanical resistance, good wear resistance, high elastic modulus, good flexibility and a very good ozone and oxidation resistance.

| Chemical resistance | Pure aliphatic hydrocarbons (propane, butane) Mineral oils and greases Silicone oils and greases Water up to +50°C |

|---|---|

| Compatibility issue | Ketones, esters, ethers, alcohols and glycols Hot water, steam, alkalis, amines and acids |

| Temperature range | -30°C/+90°C -30°C / +110°C with our PUHT (short term peak at 150°C) |

Nylon

DIMENSION

DIMENSION

| Internal Diameter (d) | Outside Diameter (D) | Height (H) |

|---|---|---|

| 40 | 55.5 | 6.3 |

| 45 | 60.5 | 6.3 |

| 50 | 65.5 | 6.3 |

| 55 | 70.5 | 6.3 |

| 60 | 75.5 | 6.3 |

| 65 | 80.5 | 6.3 |

| 70 | 85.5 | 6.3 |

| 75 | 90.5 | 6.3 |

| 80 | 95.5 | 6.3 |

| 85 | 100.5 | 6.3 |

| 90 | 105.5 | 6.3 |

| 95 | 110.5 | 6.3 |

| 100 | 115.5 | 6.3 |

| 105 | 120.5 | 6.3 |

| 110 | 125.5 | 6.3 |

| 115 | 130.5 | 6.3 |

| 120 | 135.5 | 6.3 |

| 125 | 140.5 | 6.3 |

| 130 | 145.5 | 6.3 |

| 132 | 147.5 | 6.3 |

| 135 | 150.5 | 6.3 |

| 140 | 155.5 | 6.3 |

| 150 | 165.5 | 6.3 |

| 160 | 175.5 | 6.3 |

| 170 | 185.5 | 6.3 |

| 180 | 195.5 | 6.3 |

| 190 | 205.5 | 6.3 |

| 200 | 221 | 8 |

| 210 | 231 | 8 |