KZT

Description

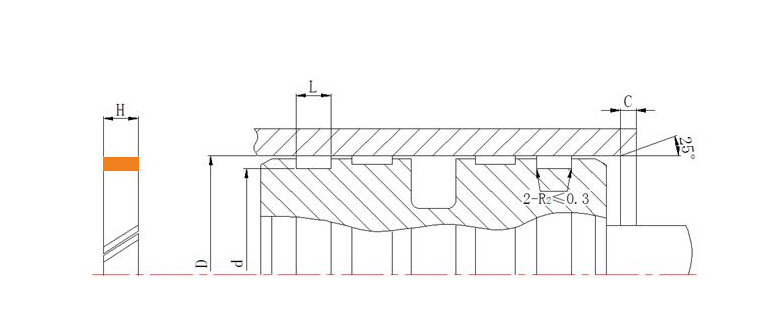

KZT is used in combination with piston seals and anti-wear rings. This product is used in combination with anti-wear and piston ring seals to prevent cylinder oil from mixing with foreign particles, resulting in seal damage and a long service life. The piston rod seal is used in combination with a metal bushing to prevent damage to the rod due to the impurity immersion function of the PTFE. It is used to move the piston and rod in the cylinder. It has good guiding effect and can absorb radial force at any time to prevent metal-metal contact in the cylinder and reduce friction. According to your specific requirements, KZT has many materials that can be used for the guide ring.

Application

Excavators

Heavy duty hydraulic cylinders

Materials

Rareflon (PTFE), PTFE Bronze compund

TECHNICAL DATA

TECHNICAL DATA

| Temperature | -55°C/+220°C |

| Pressure | MPa |

| Speed | 0 m/s |

| Medias | Mineral hydraulic oils |

MATERIALS

MATERIALS

NBR

Nitrile rubber (NBR) is the general term for acrylonitrile-butadiene copolymer. The ACN content can vary between 18% and 50%. While the acrylonitrile content is important, the resistance to oil and fuel is more so. Conversely, the elasticity and compression set are not as good. The NBR has good mechanical properties and good wear resistance. However, its resistance to atmospheric agents and the ozone is relatively low.

| Chemical resistance | Aliphatic hydrocarbons (propane, butane, petroleum, diesel fuel) Mineral oils and greases Fire-resistant fluids (HFA, HFB and HFC) Diluted acids, low-temperature alkaline and saline solutions Water (up to +100°C max) |

|---|---|

| Compatibility issue | Fuels with high aromatic content Aromatic hydrocarbons (benzene) Chlorinated hydrocarbons (trichlorethylene) Polar solvents (ketone, acetone, acetic acid, ethylene-ester) Strong acids Glycol-based brake fluids Atmospheric and ozone agents |

| Temperature range | -25°C/+100°C |

PTFE

| Friction ring | Profiled seal | Contact surface area | ||||

|---|---|---|---|---|---|---|

| Code | Type of material | Colour | Code | Type of material | Service temperature | |

| DB | PTFE + 60% Bronze | Dark brown | K8 | NBR 80 Shore A | -30°C/+100°C | Steel, chrome steel, Cast iron |

DIMENSION

DIMENSION

| Internal Diameter (d) | Outside Diameter (D) | Height (H) |

|---|---|---|

| 70 | 62 | 4 |

| 85 | 77 | |

| 90 | 82 | |

| 95 | 87 | |

| 100 | 92 | |

| 110 | 102 | |

| 80 | 72 | 6 |

| 95 | 87 | |

| 100 | 92 | |

| 105 | 97 | |

| 110 | 102 | |

| 115 | 107 | |

| 120 | 112 | |

| 125 | 117 | |

| 130 | 122 | |

| 135 | 127 | |

| 140 | 132 | |

| 145 | 137 | |

| 150 | 142 | |

| 160 | 152 | |

| 165 | 157 | |

| 170 | 162 | |

| 170 | 162 | |

| 175 | 167 | |

| 175 | 167 | |

| 200 | 192 | |

| 140 | 132 | 6.0-PTFE |

| 150 | 142 | |

| 160 | 152 | |

| 170 | 162 | |

| 180 | 172 | |

| 100 | 92 | 8 |

| 110 | 102 | |

| 115 | 107 | |

| 120 | 112 | |

| 125 | 117 | |

| 130 | 122 | |

| 135 | 127 | |

| 140 | 132 | |

| 145 | 137 | |

| 150 | 142 | |

| 160 | 152 | |

| 190 | 182 | |

| 160 | 152 | 9 |

| 170 | 162 | |

| 180 | 172 | |

| 90 | 82 | 9.5 |

| 95 | 87 | |

| 100 | 92 | |

| 105 | 97 | |

| 110 | 102 | |

| 120 | 112 | |

| 125 | 117 | |

| 130 | 122 | |

| 135 | 127 | |

| 140 | 132 | |

| 145 | 137 | |

| 150 | 142 | |

| 160 | 152 | |

| 165 | 157 | |

| 170 | 162 | |

| 180 | 172 | |

| 190 | 182 | |

| 195 | 187 | |

| 200 | 192 | |

| 215 | 207 | |

| 225 | 217 | |

| 85 | 77 | 12 |

| 80 | 72 | 15 |

| 85 | 77 | |

| 90 | 82 | |

| 95 | 87 | |

| 100 | 92 | |

| 105 | 97 | |

| 110 | 102 | |

| 115 | 107 | |

| 120 | 112 | |

| 125 | 117 | |

| 130 | 122 | |

| 135 | 127 | |

| 140 | 132 | |

| 230 | 222 | |

| 240 | 232 | |

| 260 | 252 |