DC4

Description

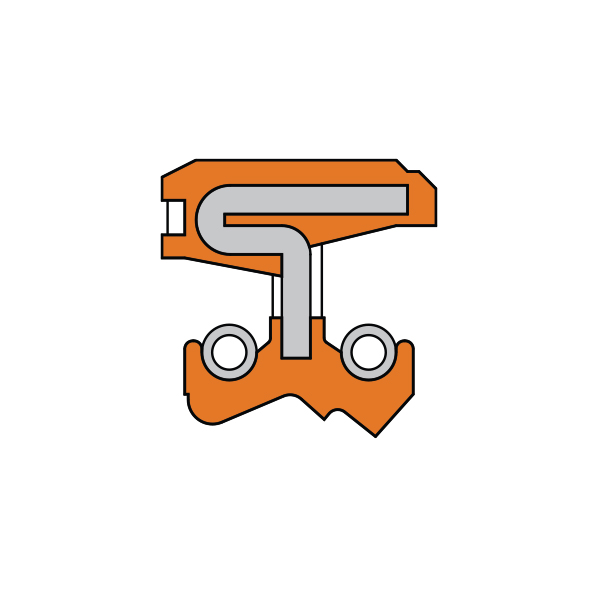

The DC4 profile is a shaft seal composed of a single metal cage with a rubber coating and a double sealing lip suitable for linear movements, the fluids being separated by the integrated springs.

* Very good static sealing

* Very good thermal expansion compensation

* Greater roughness is allowed in the housing

* Reduced risk of corrosion

* Sealing for low and high viscosity fluids

* Modern sealing lips with low radial forces

* Sealing lips designed for linear movements

* Fluid separation system

Application

All types of linear applications

Shock absorbers

Power-assisted steering

Materials

Rubber

FKM 75 – 80 Shore A

HNBR 75 – 80 Shore A

NBR 75 – 80 Shore A

Metal cage

Steel – AISI 1010

Steel – DC01 C490

Steel – DC01 C590

Spring

Steel – AISI 1070 – 1090

Stainless steel – AISI 316

TECHNICAL DATA

TECHNICAL DATA

| Temperature | -25°C/+200°C |

| Pressure | 50 MPa |

| Speed | 0.2 m/s |

| Medias | Mineral hydraulic oils |

MATERIALS

MATERIALS

ACM

Polymers containing ethyl acrylate (or butyl acrylate) have a small amount of monomer, which is necessary for cross-linking; ACM is a material with better heat resistance than NBR. It is often used for automatic gearboxes.

| Chemical resistance | Mineral oils (motor oils, gear box oils, ATF oils) Atmospheric and ozone agents |

|---|---|

| Compatibility issue | Glycol-based brake fluids (Dot 3 & 4) Aromatic and chlorinated hydrocarbons Water and steam Acids, alkalis and amines |

| Temperature range | -25°C to + 150°C (short-term peak at +160°C) -35°C / +150°C with particular ACMs |

EPDM

As an Ethylene Propylene Diene Monomer copolymer, EPDM is commonly used for hot water taps, cooling systems, brake systems, dishwashers and washing machines.

| Chemical resistance | Hot water and steam up to +150°C Glycol-based brake fluids (Dot 3 & 4) and silicone-based brake fluids (Dot 5) Organic and inorganic acids Cleaning agents, sodium and potassium alkalis Hydraulic fluids (HFD-R) Silicone oils and greases |

|---|---|

| Compatibility issue | Mineral oils and greases Hydrocarbons Low impermeability to gas |

| Temperature range | -45°C / +150°C (short-term peak at +175°C) |

FKM

Depending on their structure and fluorine content, the chemical resistance and resistance to the cold in fluororubbers can vary. This FKM-based rubber is very often used for high-temperature hydraulics and pneumatics, for industrial valves, injection/fuel systems, motor seals and high-vacuum systems.

| Chemical resistance | Mineral oils and greases, ASTM n°1, IRM 902 and IRM 903 oils. Fire-resistant liquids (HFD) Silicone oils and greases Mineral and vegetable oils and greases Aliphatic hydrocarbons (propane, butane, petroleum) Aromatic hydrocarbons (benzene, toluene) Chlorinated hydrocarbons (trichlorethylene) Fuel (including high alcohol content) Atmospheric and ozone agents |

|---|---|

| Compatibility issue | Glycol-based brake fluids. Ammonia gas. Organic acids with a low molecular weight (formic and acetic acids) |

| Temperature range | -20°C / +200°C (short-term peak at +230°C) -40°C / +200°C with particular FKMs |

HNBR

This HNBR-based rubber is obtained through selective hydrogenation of the NBR’s butadiene groups. It is commonly used for power-assisted steering and for air conditioning.

| Chemical resistance | Aliphatic hydrocarbons Mineral and vegetable oils and greases Fire-resistant fluids (HFA, HFB and HFC) Diluted acids, saline solutions and bases for operation at an average temperature Water and steam up to +150°C Atmospheric and ozone agents |

|---|---|

| Compatibility issue | Chlorinated hydrocarbons Polar solvents (ketones, esters and ethers) Strong acids |

| Temperature range | -30°C / +150°C (short-term peak at +160°C) -40°C / +150°C with particular HNBRs |

NBR

Nitrile rubber (NBR) is the general term for acrylonitrile-butadiene copolymer. The ACN content can vary between 18% and 50%. While the acrylonitrile content is important, the resistance to oil and fuel is more so. Conversely, the elasticity and compression set are not as good. The NBR has good mechanical properties and good wear resistance. However, its resistance to atmospheric agents and the ozone is relatively low.

| Chemical resistance | Aliphatic hydrocarbons (propane, butane, petroleum, diesel fuel) Mineral oils and greases Fire-resistant fluids (HFA, HFB and HFC) Diluted acids, low-temperature alkaline and saline solutions Water (up to +100°C max) |

|---|---|

| Compatibility issue | Fuels with high aromatic content Aromatic hydrocarbons (benzene) Chlorinated hydrocarbons (trichlorethylene) Polar solvents (ketone, acetone, acetic acid, ethylene-ester) Strong acids Glycol-based brake fluids Atmospheric and ozone agents |

| Temperature range | -30°C / +100°C (short-term peak at +120°C) -40°C / +100°C with particular NBRs |

METAL CAGE

| Application | Material | Standard | Characteristics |

| Metal cage | Non-alloy standard steel | AISI 1010 (DIN 1624) |

Cold rolled steel |

| Metal cage | Nickel chrome steel | AISI 304 (DIN 1.4301 – V2A) |

Standard stainless steel |

| Metal cage and spring | Chrome-nickel-molybdenum steel | AISI 316 (DIN 1.4401 – V4A) |

Stainless steel highly resistant to corrosion |

| Spring | Steel for springs | AISI 1070 – 1090 DIN 17223 |

Cold drawn carbon steel wire |

| Spring | Nickel chrome steel | AISI 302 (DIN 1.4300) |

Stainless steel for springs with a high carbon content |

DIMENSION

DIMENSION

| Item | Internal Diameter (d) | Outside Diameter (D1 H8) | Height (H) |

|---|---|---|---|

| DC4 20 x 30 x 10 | 20 | 30 | 10 |

| DC4 22 x 36 x 10 | 22 | 36 | 10 |

| DC4 26 x 37 x 10.5 | 26 | 37 | 10.5 |

| DC4 27 x 37 x 10.5 | 27 | 37 | 10.5 |

| DC4 27 x 39 x 10.5 | 27 | 39 | 10.5 |

| DC4 27 x 40 x 10.5 | 27 | 40 | 10.5 |

| DC4 28 x 40 x 11 | 28 | 40 | 11 |

| DC4 30 x 41 x 10 | 30 | 41 | 10 |

| DC4 30 x 42 x 11 | 30 | 42 | 11 |

| DC4 31 x 43 x 10.3 | 31 | 43 | 10.3 |

| DC4 32 x 43 x 10.5 | 32 | 43 | 10.5 |

| DC4 32 x 44 x 10.5 | 32 | 44 | 10.5 |

| DC4 32 x 46 x 11 | 32 | 46 | 11 |

| DC4 33 x 45 x 11 | 33 | 45 | 11 |

| DC4 33 x 46 x 10.5 | 33 | 46 | 10.5 |

| DC4 33 x 46 x 11 | 33 | 46 | 11 |

| DC4 35 x 46 x 11 | 35 | 46 | 11 |

| DC4 35 x 47 x 10 | 35 | 47 | 10 |

| DC4 35 x 48 x 11 | 35 | 48 | 11 |

| DC4 36 x 50 x 11 | 36 | 50 | 11 |

| DC4 37 x 50 x 11 | 37 | 50 | 11 |

| DC4 38 x 50 x 8 | 38 | 50 | 8 |

| DC4 38 x 50 x 10.5 | 38 | 50 | 10.5 |

| DC4 39 x 52 x 11 | 39 | 52 | 11 |

| DC4 40 x 52 x 10.5 | 40 | 52 | 10.5 |

| DC4 41 x 53 x 8 | 41 | 53 | 8 |

| DC4 41 x 54 x 11 | 41 | 54 | 11 |

| DC4 42 x 55 x 11 | 42 | 55 | 11 |

| DC4 43 x 54 x 11 | 43 | 54 | 11 |

| DC4 43 x 55 x 9.5 | 43 | 55 | 9.5 |

| DC4 43 x 55 x 10.5 | 43 | 55 | 10.5 |

| DC4 45 x 57 x 11 | 45 | 57 | 11 |

| DC4 45 x 58 x 11 | 45 | 58 | 11 |

| DC4 46 x 58 x 9.5 | 46 | 58 | 9.5 |

| DC4 46 x 58 x 10.5 | 46 | 58 | 10.5 |

| DC4 47 x 58 x 10 | 47 | 58 | 10 |

| DC4 48 x 58 x 8.5 | 48 | 58 | 8.5 |

| DC4 48 x 58 x 9.5 | 48 | 58 | 9.5 |

| DC4 50 x 60 x 7 | 50 | 60 | 7 |

| DC4 50 x 63 x 11 | 50 | 63 | 11 |