TBP

Description

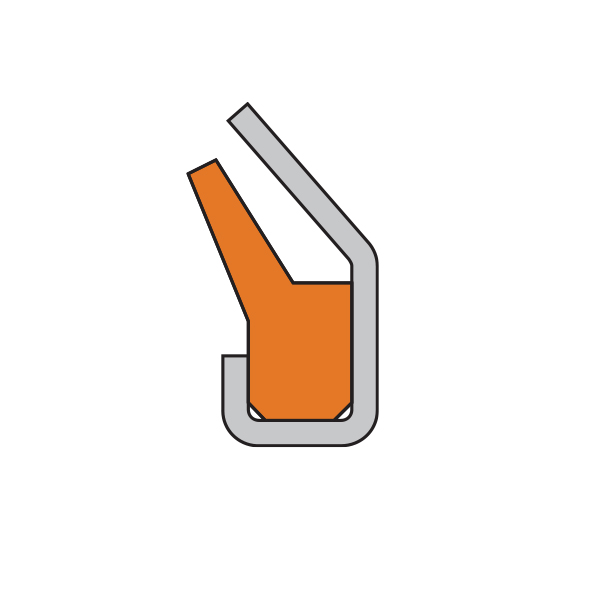

The design of the most commonly used GAMMA Seal TBP /RB is based on many years of experience in such applications. The total axial force of the sealing lip is given by elastomer prestretching together with lip deformation force which depends on the elasticity of the rubber material, geometry of the sealing lip and assembly positioning against the counter-face. The metal shell is protecting the seal from solids and contributes to exclude other pollution media by centrifusion, allowing a good drainage after immersion in liquids.

* Good dynamic sealing

* Very good protection against solid pollution particles

* Modern lip design provides low axial forces (low power loss)

* Small fitting width

* No supplementary retention’s needed

Application

Transmission systems (e.g. gearboxes)

Pumps

Electrical motors

Machine tools

Wheels and heavy-duty axles

Materials

Fluorinated Rubber (FKM) + Nitrile Rubber (NBR)

TECHNICAL DATA

TECHNICAL DATA

| Temperature | -40°C/+200°C |

| Pressure | 0 MPa |

| Speed | 20 m/s |

| Medias | Mineral and synthetic Lubricants |

MATERIALS

MATERIALS

FKM

Depending on their structure and fluorine content, the chemical resistance and resistance to the cold in fluororubbers can vary. This FKM-based rubber is very often used for high-temperature hydraulics and pneumatics, for industrial valves, injection/fuel systems, motor seals and high-vacuum systems.

| Chemical resistance | Mineral oils and greases, ASTM n°1, IRM 902 and IRM 903 oils. Fire-resistant liquids (HFD) Silicone oils and greases Mineral and vegetable oils and greases Aliphatic hydrocarbons (propane, butane, petroleum) Aromatic hydrocarbons (benzene, toluene) Chlorinated hydrocarbons (trichlorethylene) Fuel (including high alcohol content) Atmospheric and ozone agents |

|---|---|

| Compatibility issue | Glycol-based brake fluids. Ammonia gas. Organic acids with a low molecular weight (formic and acetic acids) |

| Temperature range | -20°C / +200°C (short-term peak at +230°C) -40°C / +200°C with particular FKMs |

NBR

Nitrile rubber (NBR) is the general term for acrylonitrile-butadiene copolymer. The ACN content can vary between 18% and 50%. While the acrylonitrile content is important, the resistance to oil and fuel is more so. Conversely, the elasticity and compression set are not as good. The NBR has good mechanical properties and good wear resistance. However, its resistance to atmospheric agents and the ozone is relatively low.

| Chemical resistance | Aliphatic hydrocarbons (propane, butane, petroleum, diesel fuel) Mineral oils and greases Fire-resistant fluids (HFA, HFB and HFC) Diluted acids, low-temperature alkaline and saline solutions Water (up to +100°C max) |

|---|---|

| Compatibility issue | Fuels with high aromatic content Aromatic hydrocarbons (benzene) Chlorinated hydrocarbons (trichlorethylene) Polar solvents (ketone, acetone, acetic acid, ethylene-ester) Strong acids Glycol-based brake fluids Atmospheric and ozone agents |

| Temperature range | -25°C/+100°C |

DIMENSION

DIMENSION

[

| Item | d1 | d2 | b | B1 | d max |

|---|---|---|---|---|---|

| TBP000100 | 10 | 24 | 3.5 | 1 | 15 |

| TBP000120 | 12 | 26 | 3.5 | 1 | 17 |

| TBP000150 | 15 | 30 | 4 | 1 | 21 |

| TBP000160 | 16 | 32 | 4 | 1 | 23 |

| TBP000170 | 17 | 32 | 4 | 1 | 23 |

| TBP000180 | 18 | 33 | 4 | 1 | 24 |

| TBP000200 | 20 | 35 | 4 | 1 | 26 |

| TBP000220 | 22 | 40 | 4 | 1 | 28 |

| TBP000240 | 24 | 40 | 4 | 1 | 30 |

| TBP000250 | 25 | 40 | 4 | 1 | 31 |

| TBP000260 | 26 | 40 | 4 | 1 | 32 |

| TBP000280 | 28 | 43 | 4 | 1 | 34 |

| TBP000300 | 30 | 47 | 4.5 | 1 | 37 |

| TBP000320 | 32 | 49 | 4.5 | 1 | 39 |

| TBP000350 | 35 | 52 | 4.5 | 1 | 42 |

| TBP000400 | 40 | 57 | 4.5 | 1 | 47 |

| TBP000450 | 45 | 62 | 4.5 | 1 | 52 |

| TBP000480 | 48 | 65 | 4.5 | 1 | 55 |

| TBP000500 | 50 | 70 | 5.5 | 1 | 58 |

| TBP000520 | 52 | 72 | 5.5 | 1 | 60 |

| TBP000530 | 53 | 73 | 5.5 | 1 | 61 |

| TBP000550 | 55 | 75 | 5.5 | 1 | 63 |

| TBP000580 | 58 | 78 | 5.5 | 1 | 66 |

| TBP000600 | 60 | 80 | 5.5 | 1 | 67 |

| TBP000620 | 62 | 82 | 5.5 | 1 | 70 |

| BP000650 | 65 | 85 | 5.5 | 1 | 73 |

| BP000680 | 68 | 88 | 5.5 | 1 | 76 |

| BP000700 | 70 | 90 | 5.5 | 1 | 78 |

| BP000720 | 72 | 92 | 5.5 | 1 | 80 |

| TBP000750 | 75 | 95 | 5.5 | 1 | 83 |

| TBP000780 | 78 | 98 | 5.5 | 1 | 86 |

| TBP000800 | 80 | 100 | 5.5 | 1 | 88 |

| TBP000850 | 85 | 105 | 5.5 | 1 | 93 |

| TBP000900 | 90 | 110 | 5.5 | 1 | 98 |

| BP000950 | 95 | 115 | 5.5 | 1 | 103 |

| BP001000 | 100 | 120 | 5.5 | 1 | 108 |

| BP001050 | 105 | 125 | 5.5 | 1 | 113 |

| TBP001250 | 125 | 148 | 6.5 | 1 | 133 |

| BP001350 | 135 | 159 | 6.5 | 1 | 145 |